AWA: Academic Writing at Auckland

Title: Sarsen stones at Stonehenge III

|

Copyright: Bhumika Mistry

|

Description: The research assignment required an essay topic of my own choice within the broad subject area of Pre-modern architecture and urbanism. The essay required scholarly sources and the careful organisation of material both texts and the images. The focus of the essay was to select a part of the chosen building or typology, and further expand our understanding in a particular area. The essay also required an original comparative analysis and reference to other historical structures.

Warning: This paper cannot be copied and used in your own assignment; this is plagiarism. Copied sections will be identified by Turnitin and penalties will apply. Please refer to the University's Academic Integrity resource and policies on Academic Integrity and Copyright.

Sarsen stones at Stonehenge III

|

The last decade of investigation of the sarsen stones construction and technologies at Stonehenge III

Stonehenge is a unique prehistoric monument, that stands in the midst of Salisbury plain, Wiltshire UK, whose origins began from the middle Neolithic age of around 2900 BC.[1] The name Stonehenge, which is of Saxon origin is derived from the idea of ‘hanging stones’[2]. Stonehenge is the result of a series of significant projects over more than a millennium and serves as a sacred ceremonial cemetery, observatory of the moon and as a sun temple, signifying the idea of eternity.[3] The ranging era of the Stonehenge from early Neolithic to Iron age exhibits the newest assessment of the construction where communities stretch their physical and natural resources to an extreme end to compose such megalithic stone structures. It is from the main processes and stages of transportation, dressing and the erection of the stones that we are critically informed on how the mass of stones and complexion of the form was achieved on site. This essay will be discussing the extraordinary manual and mechanical techniques applied in the construction of the Stonehenge, and how these techniques and materials set together the fabric of the sarsen trilithons in this ancient monument.

The dominant stones that give Stonehenge it’s remarkable visual impact are the sarsens, which are purely natural blocks of sandstone that consist of fine grain with strong siliceous material.[4] Sarsen Trilithons stand at the centre of the monument in a horseshoe of five individual pairs.[5][Figure 1] These Trilithons were the first to be erected at the Stonehenge and were universally shaped, dressed and erected with laboriously complex construction techniques.

Stonehenge has been augmented over centuries however, has conserved its original design of a circle with an axial approach that is aligned to an important social feature - the midsummer sun, allowing the regularity of the construction to be speculated as a sun temple.[6] The general understanding of stones in the Sarsen circle is that these constructions of slabs are effectively dressed in orthogonal form with convex faces. However, to compose and shape these stone structures was a process that was made possible through new building tools and technologies and transportation methods that were available at the time but also met cultural needs. The very large Sarsen blocks were employed from overland roughly 40 kms from the Marlborough downs.[7] The huge blocks of stone were largely from bedrock and the process of extracting these blocks from surface outcrops is thought to have been detached in an extensive measure with the splitting technique.[8] The technology utilised is known an ‘pyro-technology’ where cracks could be created in the stone by lighting strip fires along the desired line that has to be split, they further this by suppressing them with water and continuously dashing down heavy stones alongside for easy breakage in the chosen spot.[9] Through pyro-technology during the Neolithic period it can be stated that natural cleavage techniques adopted allowed the blocks so hard and delimited to be split from the mass of rock. Therefore, it could be claimed that the absence of metal tools during that period was not significant due to the difficulty of breakage of stone with metal tools.

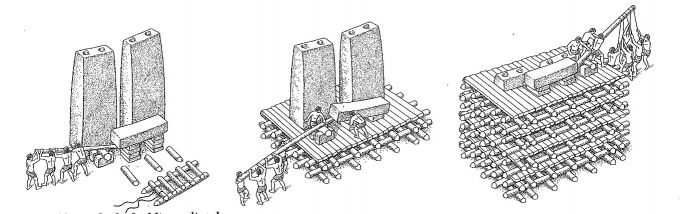

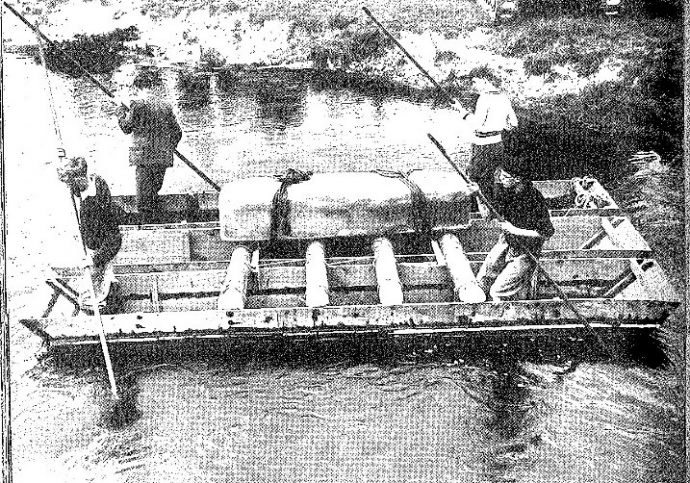

The techniques used for the transportation of Sarsen stones onto the site held much importance. Water transportation was the primary approach as it proved to be the most economical and only means of moving heavy goods with relative speed. However, the Sarsen stones weigh upto 5-7 tonnes, therefore preliminary work of dressing was necessary to reduce the width of natural stone into a pillar-like shape with the required dimensions to minimise the load.[10] Specially constructed rafts were vital in this situation for the carriage of Sarsen stones on the challenging route along the south coast of wales and up the Bristol channel finally leading to the Avon.[11] The rafts were carefully constructed by skilled craftsman with solid logs lashed together in two layers, one laid at right angles to the other.[12] [Figure 2] The minimum sizing of the log rafts was determined by the load of the heaviest Sarsen stone with that of the appropriate crew transporting them. However, manpower played a critical role in this stage as humans were the only available source of traction to transfer the stones onto rafts. They executed this with the use of hide ropes that were produced in great quantities from twisted and interwoven strips of hide.[13] Furthering this, the method in which the Sarsen stones were transported into position on the site required some sort of sled, by which the stones were pulled along a wooden trackway that was coated in animal fat.[14][Figure 3] These specially constructed tracks conserved much of the workforce’s power and labour but also exemplifies the knowledge of craftsmanship that could be considered as a technological capital passed down to Neolithic builders from Palaeolithic ancestors.[15]

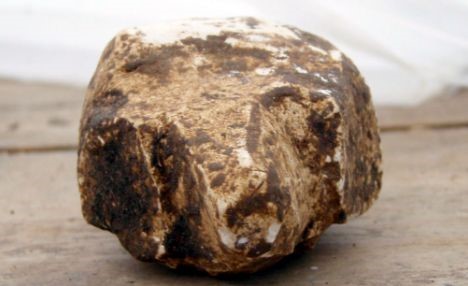

The next technological considerations are those addressed with the cutting and dressing of the Sarsen stones on the site. The Sarsens are dressed into tabular slab like forms, with two parallel faces.[16] The cutting of stone was carried out where a natural crack was evident, this crack would be deepened by pecking with stone tools and driving in wooden wedges to deepen the crack causing the stone to be cut. This involved two main processes of splitting and abrading, the technique of splitting the stone into a neat shape through fire operation has been defined, however abrading is a more simplistic approach of shaping and surfacing the hardstone into a smooth surface requiring labour intensive work.[17] These techniques were used earlier in fashioning stone instruments and therefore developed during the earliest Neolithic times. The chief technique of dressing the stone was through very laborious pounding with stone mauls, [Figure 4] these were usually flattened spheres of sarsen stones that were batted all over providing evident clues of the manner in which they were used.[18] However, within the finding of archaeologists there is evidence of tools such as stone hammers that were deposited as packing-blocks below the surface in the stone holes.[19] Applying such a primitive technique of pounding to dress the stone can be dictated to the intractable nature of the sarsen stones themselves, but we can also claim that this particular craft of dressing was taken from the contemporary urban civilizations of the Mediterranean as the practice of dressing stones in this technique with similar tools was already well established during that period.[2

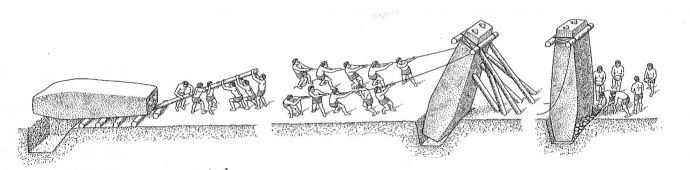

The technology of erection of the Sarsen stones is the most crucial, as they believed that the fitting of the stones was a over engineered built solution where builders applied more wood-working techniques than stone-working. This consciously chosen method employed to work in wood was seen as a link to ritual, power and continuity in the design.[21] The erection however, involved two distinct tasks, to bed stably and position upright piers. The stones would be brought from the outside circle to stone holes whose depth was carefully adjusted prior to the erection using antler picks. The internal face of the stone hole was aligned with wooden stakes for the purpose of protecting the chalk side but to also prevent crushing or collapse of the stone during the operation.[22] The outer face of the stone-hole was dug at 45 degrees forming a sloped back edge,[23] this operated as a ramp for a more smoother transition of the erection. The Sarsens were supported horizontally on rollers of a large diameter, hide ropes were attached to the top of the stone levering, and hauling it vertically upright into position with a large team of men and brute force.[Figure 5] To diminish the effort required strong timber shear legs in the form of a ‘A-frame’ roughly the height of the stone were located on the inward side of the stone hole.[24] From previous findings, it is evident that stone holes were packed with sarsen stone mauls to secure the base with the vertical upright. Through the process of erection of the sarsens it is evident how such megalithic stone construction extensively depends on woodworking.

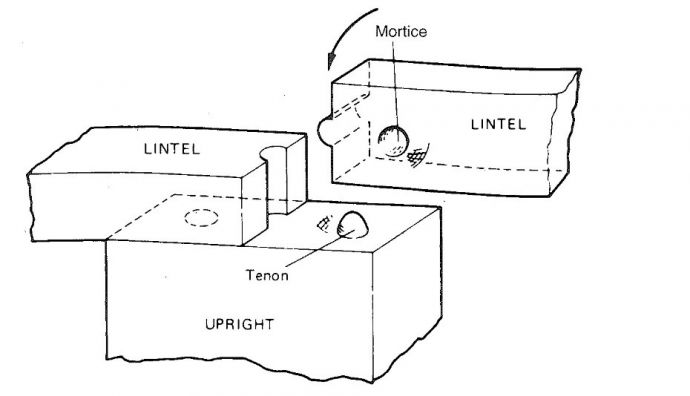

To raise the lintel blocks on top of the Piers for the Trilithon was complex as there were a combination of techniques, instruments and equipment required. The seating of the sarsen on top of the piers aligned together on one plane was important to have them fixed together. The builders opted a more laborious task with the ‘in-situ’ approach to fix the lintels to the piers by forming the mortise-and-tenon and tongue and groove joint on the sarsens. The production of the joints took place after the erection of the uprights with similar techniques of pounding and grinding shaping the tenon by careful removal of the top of the stone to ensure that the fixings held together and gave the trilithon additional strength.[25][Figure 6] The conventional manner in which the lintels were raised into position was through gradually raising the stone on a wooden crib. The lintels would initially stand on a platform of timber parallel with the vertical uprights, with the help of levers each end would alternatively be lifted and placed on a wooden deck with criss crossed timbers, this method would be repeated until the sarsen lintel was raised to the height of the vertical.[26] [Figure 7] Additional manoeuvre would be required to fit the lintel onto the projecting tenon. Furthering this, archaeological findings of excavated ground around the stones also suggests that there was an alternative method of constructing the lintels on the vertical sarsens. Although the earth ramps were primarily used for placing the stone into its original hole, the hypothesis may be that earthen ramps were equally used to drag the lintel up the slope and onto the piers.[27] This notion, seems to be derived from the belief that this method of construction was used in dynastic Egypt for erection of the colossal stone statues as well as the pyramids.

The construction techniques used in the Stonehenge are very distinct methods of construction that can be perceived in Ancient Egypt, as the approach was marked as historical succession. A wide expression of finely dressed stone and erection techniques can be seen standard from 2600 BC in the pyramid age.[28] Dressing of stone was considered important in monumental constructions of the Old Kingdom as the stone was reckoned to be a more noble material that would serve to commemorate the gods.[29] From earliest times Egyptians would quarry large blocks of hard stone, from large rock formations that are located in the remote desert regions, similar employment of techniques such ‘pyro technology’ or ‘pyro sculpture’ to split individual stone members were used.[30] As to the additional dressing methods, it is to be noted that for all hard stones from the desert regions simple tools such as hand held pounder, rammers and stone mauls of hard sandstone or limestone were used however, this required protracted labour.[31] Techniques used for erection on site were made practical and possible and we can see how the builders of Stonehenge followed the method of prepared tracks and causeways on which the blocks would be hauled on specially made sleds with man power. On the other hand archaeologists have discovered remains of embankments of earth suggesting the construction of ramps being located as installations on the site allowing the stones to be hauled into position through these ramps. This technique presented challenges as the gradient of the slope was steep, therefore an alternative solution of levering blocks onto steps by using wood works was made possible, this repetitive process of levering and chocking the stones made erection possible.[32] Through such construction techniques of pyramids, it can be made clear that ancient Egyptians possessed highly sophisticated technology, and it is reasonable to consider that the Neolithic builders of Stonehenge used these native methods of construction in a more advanced and engineered manner.

In conclusion, through the findings of archaeologists it can be made evident that the slab like components of megaliths presented very rich craftsmanship during the Neolithic period. In view we can understand that the Stonehenge showed a relatively advanced level of technology and techniques exhibited throughout construction, and although some methods such as pounding, and grinding may be seen as primitive techniques for dressing the stone it can be claimed that these techniques were applied solely due to the nature of the sarsen. Clever methods of using pyro-technology for the splitting and shaping the sarsens brought great antiquity but exemplified how such advanced thinking was applied by the builders in a time where metal implements were not available. Lastly, there are remarkable techniques and methods applied primarily to the erection and joints of the lintels, the execution in the joinery of trilithons exposes the overall design of the stones and can be seen as an engineering feature with the interlocking mortise-and-tenon joints. The significance of also opting woodworking techniques as a type of ‘scaffolding’ to erect the vertical sarsen has been reinforced by archaeological evidence with findings that many megalithic monuments such as dolmens and stone circles, were similarly produced by wooden forerunners. Overall, the technology and construction presented in the Stonehenge shows remarkable achievement for any monument in history, as well as setting new hallmarks for buildings today.

Final bibliography

Fowles, John, and Barry Brukoff. The Enigma of Stonehenge. London: Cape, 1990.

Chippindale, Christopher. Stonehenge Complete. London: Thames & Hudson, 2012.

North, John David. Stonehenge: Neolithic Man and the Cosmos. London: HarperCollinsPublishers, 2016.

Wright, George R.H. Ancient Building Technology. Vol. 1. Leiden: Brill, 2000.

Atkinson, Richard John Copland. Stonehenge. London: Penguin Books in Association with Hamish Hamilton, 1990.

Souden, David. Stonehenge: Mysteries of the Stones and Landscape. Great Britain: Collins & Brown/ English Heritage, 1997.

Clarke, D. V., Trevor G. Cowie, and Andrew Foxon. Symbols of Power at the Time of Stonehenge. Edinburgh: HMSO National Museum of Antiquities of Scotland, 1985.

Hill, Rosemary. Stonehenge. London: Profile, 2009.

Burl, Aubrey. Stonehenge: A New History of the Worlds Greatest Stone Circle. London: Constable, 2006.

Cunliffe, Barry, and Colin Renfrew. Science and Stonehenge. Oxford: Oxford University Press, 1999.

Bibliography of images:

Fig1: Chippindale, Christopher. Stonehenge Complete. London: Thames & Hudson, 2012, 172.

Fig2: Atkinson, Richard John Copland. Stonehenge. London: Penguin Books in Association with Hamish Hamilton, 1990, 95.

Fig3: North, John David. Stonehenge: Neolithic Man and the Cosmos. London: HarperCollinsPublishers, 2016.

Fig4: Chippindale, Christopher. Stonehenge Complete. London: Thames & Hudson, 2012, 178.

Fig5: Souden, David. Stonehenge: Mysteries of the Stones and Landscape. Great Britain: Collins & Brown/ English Heritage, 1997, 92.

Fig6: Chippindale, Christopher. Stonehenge Complete. London: Thames & Hudson, 2012, 12.

Fig7: Souden, David. Stonehenge: Mysteries of the Stones and Landscape. Great Britain: Collins & Brown/ English Heritage, 1997, 92.

[1] North, Stonehenge: Neolithic Man and the Cosmos, 2. [2] Chippindale, Stonehenge Complete, 10. [3] Burl, Stonehenge: A New History of the Worlds Greatest Stone Circle, 36. [4] Souden, Stonehenge: Mysteries of the Stones and Landscape, 84. [5] Ibid, 85. [6] Hill, Stonehenge, 47.. [7] Wright, Ancient Building Technology, 31. [8] Atkinson, Stonehenge, 118. [9] Wright, Ancient Building Technology, 32. [10] Atkinson, Stonehenge, 105. [11] ibid. [12] Cunliffe, Renfrew, Science and Stonehenge, 25. [13] Wright, Ancient Building Technology, 35. [14] Souden, Stonehenge: Mysteries of the Stones and Landscape, 92. [15] Wright, Ancient Building Technology, 37. [16] Fowles, Barry, The Enigma of Stonehenge, 42. [17] Atkinson, Stonehenge, 101. [18] Souden, Stonehenge: Mysteries of the Stones and Landscape, 96. [19] ibid. [20] Wright, Ancient Building Technology, 122. [21] Souden, Stonehenge: Mysteries of the Stones and Landscape, 91. [22] Wright, Ancient Building Technology, 34. [23] ibid. [24] Souden, Stonehenge: Mysteries of the Stones and Landscape, 92. [25] Chippindale, Stonehenge Complete, 169. [26] Ibid, 165. [27] Fowles, Barry, The Enigma of Stonehenge, 45. [28] Wright, Ancient Building Technology, 56. [29] Ibid, 57. [30] ibid , 62. [31] Clarke, Cowie, Foxon. Symbols of Power at the Time of Stonehenge, 173. [32] Wright, Ancient Building Technology, 62. |

Figure 2: Solid logs lashed together to create rafts for primary means of transportation.

Figure 2: Solid logs lashed together to create rafts for primary means of transportation.

Figure 4: Stone mauls made of sarsen spheres for pounding.

Figure 4: Stone mauls made of sarsen spheres for pounding.

Figure 6: Mortice and tenon joinery of the upright of piers with lintels.

Figure 6: Mortice and tenon joinery of the upright of piers with lintels.