AWA: Academic Writing at Auckland

View the papers that match the selected criteria.

Title: Roman Concrete: History, Composition, and Construction

|

Copyright: Young Ki Kim

|

Description: A research assignment on an essay topic of own choice within the broad subject area of the course (pre-modern architecture and urbanism). The essay focused on Roman concrete: its history, composition and use in construction.

Warning: This paper cannot be copied and used in your own assignment; this is plagiarism. Copied sections will be identified by Turnitin and penalties will apply. Please refer to the University's Academic Integrity resource and policies on Academic Integrity and Copyright.

Roman Concrete: History, Composition, and Construction

|

An Exploration of Opus Caementicium (Roman Concrete): History, Composition, and Construction Abstract: This research essay focusses on one of the most fundamental construction materials of ancient Rome: Concrete. Opus Caementicium or Roman Concrete was developed between the 3rd to 2nd centuries BC and became widely used on structures ranging from small domestic dwellings to the most important monumental structures still surviving to this day. This research aims to reveal the origins of the material, as a successor to the humble stone and mud mortar construction, and why it came to be used so widely in Roman structures. The physical properties of the material, and how it was created will also be analysed, referencing a variety of sources including the Roman architect Vitruvius himself. The unique and technical construction processes involved in using Roman concrete will also be discussed. Roman concrete was adopted for use in almost all structural elements, including foundations, walls, and roofs. However, this essay will concentrate more specifically on the application of Roman concrete in the construction of foundations and walls in relation to temples and in large scale buildings such as the Colosseum.

Opus Caementicium or Roman Concrete was one of the most fundamental construction materials of ancient Rome, with buildings made using this material still standing to this day almost two thousand years later. This research essay will aim to analyse the development of Roman concrete and its historical origins, and its chemical properties. The reasons for why the material came to be so widely used in ancient Rome will also be discussed. Finally, the construction methods involved in the use of Roman concrete in foundations and walls will also be detailed.

Roman concrete was introduced to Rome sometime between the 3rd to 2nd centuries BC (Malacrino, 2010). However, the origins of Roman concrete can be traced back to the humble stone and mud mortar constructions that were predominant in the Mediterranean and the Middle East from as early as the 7th century BC. This stone and mud mortar construction involved the use of three local materials in abundance: water, earth or clay, and stones. Large stones were first laid out in two horizontal lines parallel to each other, with the gap between the walls filled with more stones of varying sizes. The water and earth were mixed forming a mud mortar which was then applied as a horizontal layer on top of the stones. Once the mud had set, another layer of stone and mud could be laid on top. However, a drawback of using mud mortar was the fact that the mud would eventually lose its water content and turn to dust, leaving the stone masonry unstable. Mud mortar was also at risk of succumbing to the elements (Wright, 2000). Some houses in Pompeii from the 4th to 3rd centuries BC have been found to have used this construction in walls, albeit made with a stronger lime-based mortar filling. However, this mortar was still crude and contained earthy components with lumps of lime (Malacrino, 2010). Roman concrete can be viewed as an evolution and refinement of the construction methods mentioned above, with the key change being the replacement of the weaker mud and lime mortar with a much stronger and durable cementitious mortar. Vitruvius was aware that combining volcanic ash or pozzolana powder with lime and rubble produced a strong mortar that could set even underwater. The mixing of the ingredients created a hydraulic mortar that was waterproof, unlike a mortar made using lime which would wash away with water (Cowan, 1977).

Three key components are used in the making of Roman concrete: slaked lime, volcanic ash and aggregate. The lime for construction was created by burning stones containing calcium carbonate such as limestone, travertine or marble inside a kiln at high temperatures, turning the stones into quick lime, which when mixed with water became slaked lime. Limestone was most commonly used for this purpose and was readily available from quarries near Rome (Quenemoen & Ulrich, 2014). The key to the development of a much stronger binding material as mentioned was substituting regular sand with volcanic ash. Two different types of volcanic ash are mentioned by Vitruvius as creating a high-quality mortar. The first was a powder called pozzolana from Puteoli (now known as Pozzuoli) near Mount Vesuvius in Naples, Italy. The second, harena fosicia or pit sand was a type of volcanic ash found in the region near Rome. Along with volcanic ash, terracotta tiles and other types of ashes from organic matter were also used to a similar effect (Quenemoen & Ulrich, 2014). Roman concrete itself is likely to have developed in Puteoli, with the pozzolana initially transported from Naples to Rome, until it was found that the volcanic ash from near Rome worked just as well (Waddell, 2008). The third component, caementa or aggregates, gave Roman concrete its name; opus caementicium. Aggregates used in Roman concrete could vary from small stones to fragments of brick and terracotta pottery depending on the structural needs, but the most common and versatile was a type of limestone called tufa (Malacrino, 2010). The Romans were able to control the forces within a structure by varying the aggregates used (Quenemoen & Ulrich, 2014). For example, figure 1 shows the remnants of a concrete wall and dome at the Baths of Caracalla with various types of aggregate and facing used, with heavier materials on the lower layer, tufa in the middle, and lighter pumice near the top of the dome. Empty wine and oil jars made of clay were also incorporated into some concrete structures to further lighten the weight of the structure (Cowan, 1977). Figure 1. The remnants of a concrete wall and dome at the Baths of Caracalla in Rome showing the various layers of aggregate and facing used: brick tiles on the lower layer, tufa in the middle, and pumice near the top. Reprinted from Materialising Roman Histories (p. 143), by Astrid Oyen, 2017, Oxford, United Kingdom: Oxbow Books. Copyright 2017 by Lynne Lancaster.

Roman concrete came to be adopted rather quickly and by the time of Nero’s ruling in first century AD, it had become one of the most widely used construction materials for both public and private buildings. Several reasons can be attributed to its wide spread use. With the expansion of the city of Rome, larger spaces were required with many monumental buildings having to be constructed. Concrete was a versatile material and could be used to span wide distances not possible with stone, making it suitable for large scale constructions. The Romans, unlike the Greeks, also did not possess convenient access to marble quarries for solid stone constructions, with the most common material near Rome being soft volcanic stones such as Tufa (Sear, 1982). This could explain why the Romans adopted a mortared rubble construction, which led to concrete. There were also many economic benefits to be had from using concrete instead of stone. Compared to cut stone masonry construction, concrete construction was also less labour intensive, cheaper to produce, and the materials easier to transport. Cut stone construction required skilled labour across the extensive process of quarrying, shaping and laying, whereas concrete construction afforded the ability to use less skilled and unskilled labour during the manufacturing and construction processes – making it easier and cheaper to find workers (Waddell, 2008). This meant that projects could also be completed quicker than it could have with stone construction. With the densification of Rome, there also came a higher risk of fire. Vitruvius (2009) disapproved the wattle and daub constructions used in residential dwellings, which were susceptible to fire. Roman concrete was an economical and fireproof alternative with a relatively high strength to width ratio, making it widely adapted to the construction of private apartment buildings in Rome (Boëthius & Ward-perkins, 1970). By the time of Trajan, concrete came to be recognised as one of the most “permanent, fireproof, and inexpensive” methods of construction, and with its versatility on the construction site it became the principal material of construction in the Roman empire (Waddell, 2008, p. 43).

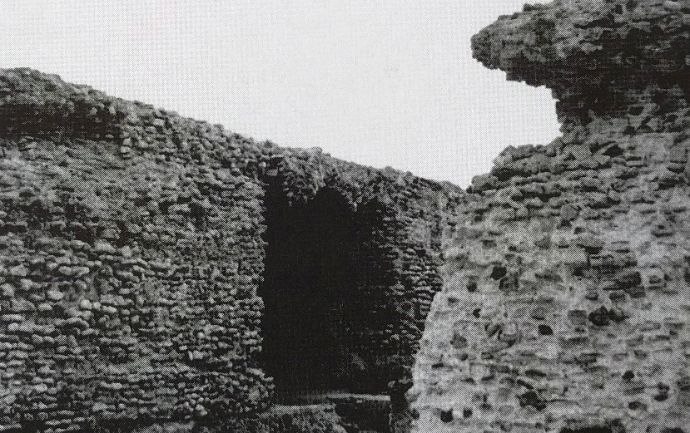

Roman concrete structures employed several methods of construction depending on the thickness and function of the structure. The most common method used in the construction of ordinary walls did not differ greatly from the earlier stone and mud mortar constructions and involved adding a layer of mortar into the core of the wall between facings, adding the aggregates to set, and covering it with another layer of mortar. This technique created an even structure with distinct horizontal layers. The intent was to let each layer set before adding another layer on top, allowing the lower layer to structurally support the next layer (Waddell, 2008). Roman concrete was used as a filling material rather than a standalone material, and as such was always used with a facing of a different material such as stone or brick. Builders created two facing walls which acted as “lost shuttering” for the concrete to be poured in, later becoming a part of the structure itself once the concrete had set (Wright, 2000, p. 117). However, this shuttering, whether in brick or stone did not play a crucial role in holding up the structure or in protecting the core structure. Once the concrete had set it acted as a single monolithic material, even without the facings. The outer facing became negligible in terms of providing load-bearing strength to the wall and structures could still stand up without the facings as seen in figure 2 (Wright, 2000).

Figure 2. Exposed concrete walls showing the fusing of the aggregate (beach stones) and mortar into a single substance at the Antonine Baths at Carthage, Tunisia, constructed in the 2nd century AD. Reprinted from Ancient building technology: Volume 1 historical background (p. 186), by George Wright, 2000, Leiden, Netherlands: Brill. Copyright 2000 by George Wright.

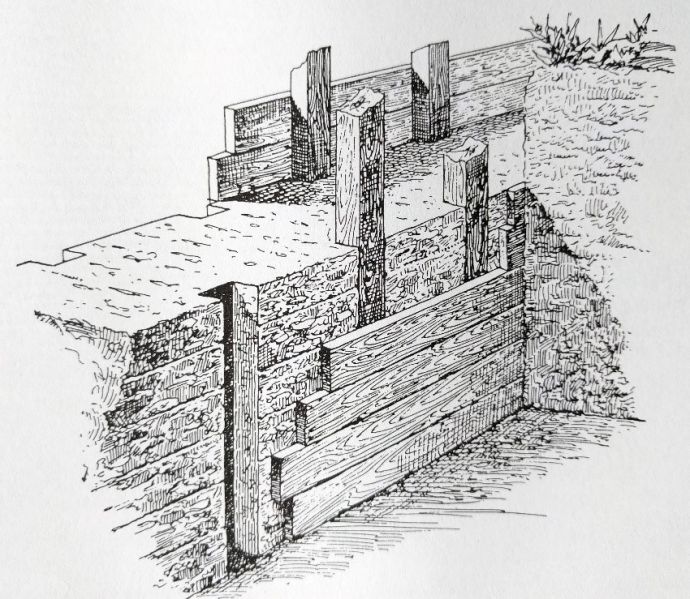

The importance of strong foundations to the overall longevity of a structure was well known by the Romans (Malacrino, 2010). Foundations of concrete faced in brick or stone or cast using timber shutters were used in both private and public Roman buildings. Trenches were generally dug until bedrock was reached or to an adequate depth for the supporting structure. Making foundations from concrete required slightly different procedures from that of using solid stone blocks. Unlike stone block foundations which required the digging of a trench wider than the foundations to accommodate the builders laying the stones, for concrete foundations, the trench could be made the same size as the structure being built on top. If the ground was even and the foundations did not require much depth, the concrete could be placed directly into the trench. For deeper foundations, a retaining wall made of timber shuttering and vertical posts was used to ensure that the walls of the trench did not collapse before the concrete was set (figure 3). The wooden formwork stayed in the ground once the concrete had set, leaving traces of its use once it had deteriorated, as can be seen in the foundation of the temple of Venus in figure 5. Figure 3. Drawing portraying the construction of a Roman concrete foundation within a trench, with reinforced shuttering used to retain the earth around the trench from collapse. Reprinted from Ancient building technology: Volume 2 materials: Part 2 illustrations (fig. 244), by George Wright, 2005, Leiden, Netherlands: Brill. Copyright 2000 by George Wright.

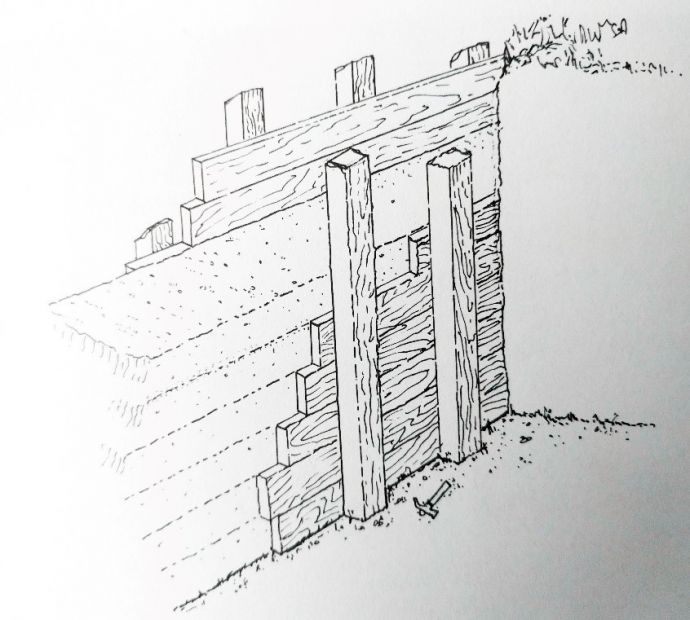

Figure 4. Drawing portraying the construction of a Roman concrete foundation that is to be above ground level, with shuttering posts on the exterior to retain the concrete mix from spreading out. Reprinted from Ancient building technology: Volume 2 materials: Part 2 illustrations (fig. 245), by George Wright, 2005, Leiden, Netherlands: Brill. Copyright 2000 by George Wright. Figure 5. The gaps where the timber stakes were placed for the formwork can be seen on the exposed foundations of the temple of Venus in Rome. Retrieved from Artstor, by Scala, 2006, Retrieved 28, Sep. 2018 from https://library-artstor-org.ezproxy.auckland.ac.nz/asset/SCALA_ARCHIVES_10310840703

For instances where the building was constructed on a sloping terrain or where the floor of the building was raised above the ground, the concrete foundation was required to extend above the trench. This was done using formworks much like the trench foundations, but the vertical poles would be placed on the exterior side rather than on the interior to hold back the force of the concrete from spreading out as can be seen in figure 4 (Malacrino, 2010).

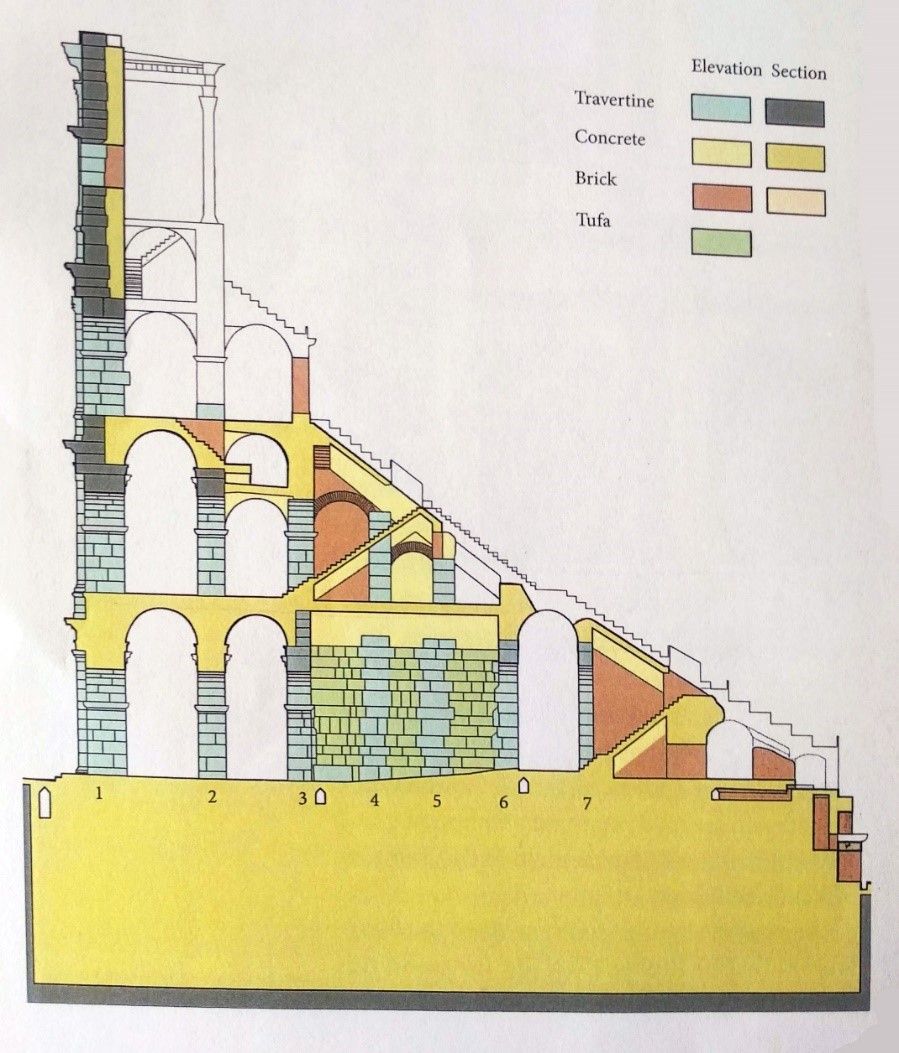

In the case of a monumental structure like the colosseum, the foundation took the form of a concrete bed spanning 60 metres wide and 12 metres deep (Quenemoen & Ulrich, 2014). The cross-section in figure 6 exposes the grand extent of this foundation. As the Colosseum was built over what was previously an artificial pond of Nero’s domus aurea, large efforts were specifically made into making sure that the foundations could support the load of the structures above. The foundations were made of separate lower and upper rings, with brick facings on the upper rings. A foundation of this scale required at least 3,000 workers in just removing the roughly 269,000 cubic metres of earth from the ground. Without the use of concrete in the foundations, the construction of the Colosseum would have been a much more difficult task, with the added costs in labour and materials required for a stone foundation in such a magnitude rendering it unrealistic or taking many more years to construct (Malacrino, 2010). Figure 6. A cross section showing the substructure systems used in the Colosseum. Reprinted from Constructing the ancient world: Architectural techniques of the Greeks and Romans (p. 120), by Carmelo Malacrino, 2010, Los Angeles, United States: Getty. Copyright 2010 by Carmelo Malacrino.

To conclude, this research essay discussed the development of Roman concrete and its historical origins, chemical components, and the reasons for why the material came to be so widely used in ancient Rome. The construction methods involved in the use of Roman concrete were also analysed, with focus on its use on foundations. The Romans were able to turn the humble stone and mud construction into a universal construction method through concrete, used on small-scale and monumental structures alike, many of which have lasted to this day; a true testament to the strength and durability of the material. Roman concrete was an endearing material, and one which continues to be used in our modern day and age albeit in a different form, but likewise, helping to push the boundaries of construction.

Bibliography

Adam, J. (1994). Roman building: Materials and techniques. London, United Kingdom: B.T. Batsford. Boëthius, A., & Ward-perkins, J. (1970). Etruscan and Roman architecture. London, United Kingdom: Penguin Books. Cowan, H. (1977). The master builders: A history of structural and environmental design from ancient Egypt to the nineteenth century. New Jersey, United States: John Wiley & Sons Delatte, N. (2001). Lessons from Roman Cement and Concrete. Journal of Professional Issues in Engineering Education & Practice, 127(3), 109-115. Retrieved from https://ascelibrary.org/doi/10.1061/%28ASCE%291052-3928%282001%29127%3A3%28109%29 Delatte, N. (2002). Lessons from Roman cement and concrete. Ingersoll, R., & Kostof, S. (2013). World Architecture: A Cross-cultural History. Oxford, United Kingdom: Oxford University Press. Jones, M. (2000). Principles of Roman architecture. New Haven, United States: Yale University Press. Lancaster, L. (2005). Concrete vaulted construction in imperial Rome: Innovation in context. New York, United States: Cambridge University Press. Malacrino, C. (2010). Constructing the ancient world: Architectural techniques of the Greeks and Romans. Los Angeles, United States: Getty McKay, A. (1978). Vitruvius, architect and engineer: Buildings and building techniques in Augustan Rome. Bristol, United Kingdom: Bristol Classical Press. Oyen, A., & Pitts, M. (Eds.). (2017). Finding the material in ‘material culture’: Form and matter in Roman concrete. Materialising Roman Histories, 133-152. Oxford, United Kingdom: Oxbow Books. Retrieved from http://www.jstor.org.ezproxy.auckland.ac.nz/stable/j.ctt1v2xtgh.15 Palley, R. (2010). Concrete: A seven-thousand-year history. New York, United States: The Quantuck Lane Press Plommer, H. (1973). Vitruvius and later Roman building manuals. Cambridge, United Kingdom: Cambridge University Press. Quenemoen, C., & Ulrich, R. (Eds.). (2014). A companion to Roman architecture. Chichester, United Kingdom: Blackwell Rook, T. (2013). Roman building techniques. Gloucestershire, United Kingdom: Amberley. Scala. (2006), Temple of Venus and Rome [Online image]. Retrieved from https://library-artstor-org.ezproxy.auckland.ac.nz/asset/SCALA_ARCHIVES_10310840703 Sear, F. (1982). Roman architecture. New York, United States: Cornell University Press. Vitruvius, M. (2009). On architecture (R. Schofield, Trans.). London, United Kingdom: Penguin Books. Waddell, G. (2008). Creating the Pantheon: Design, materials and construction. Rome, Italy: L'Erma di Bretschneider. Wright, G. (2000). Ancient building technology: Volume 1 historical background. Leiden, Netherlands: Brill. Wright, G. (2005). Ancient building technology: Volume 2 materials: Part 2 illustrations. Leiden, Netherlands: Brill. Wright, G. (2005). Ancient building technology: Volume 2 materials: Part 1 text. Leiden, Netherlands: Brill. Wright, G. (2005). Ancient building technology: Volume 3 construction: Part 1 text. Leiden, Netherlands: Brill. |